Use two 5 pound electrodes and place them on the most commonly used area of the surface.

Esd floor testing procedure.

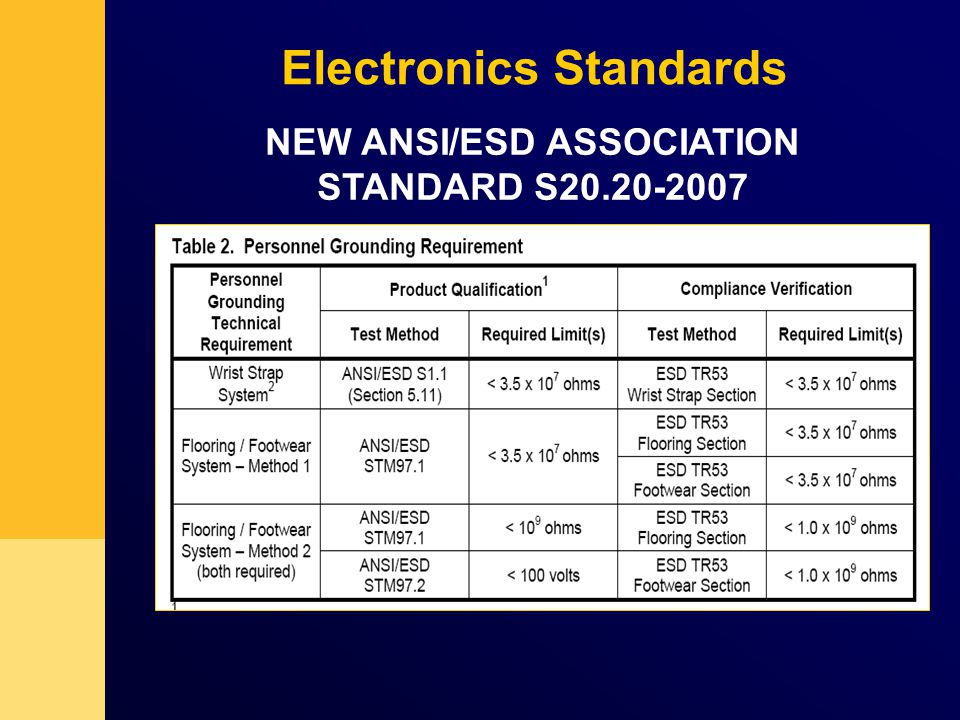

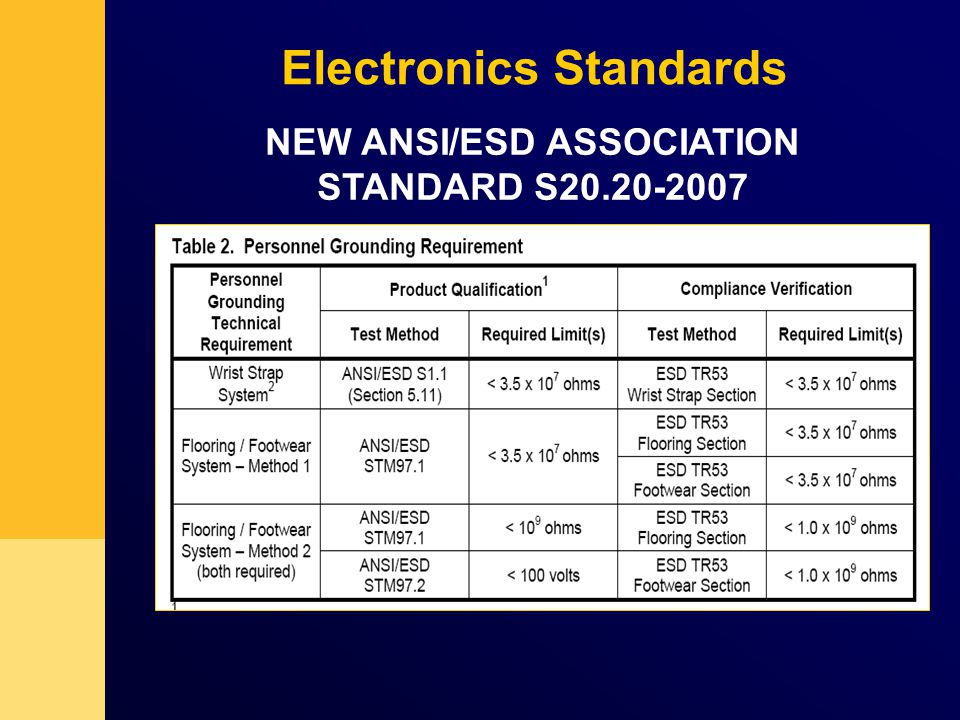

Additionally our auditing team members have been trained on how to properly perform esd control measurements as required by ansi esd s20 20 and iec 61340 5 1 esd program standards including.

To perform this test the garment should be electrically isolated laying on an insulative surface.

The minimal definition of an esd smock is that it is static dissipative.

Current flooring test procedures and the information they provide can be misleading.

Remove from the surface only those items that might interfere with the test.

5 reasons to put vermont slate on your esd flooring short list for 24 7 critical environments how is commercial carpet different from esd carpet testing and certification of esd floors buying esd flooring on the internet the case against overly.

Don t even think about making decisions without first testing the material following procedures in this test method.

Test procedure in accordance with ansi esd s4 1 section 6 4 periodic worksurface testing.

A proposed test methodology for floor materials.

Overview learn about esd flooring short videos conductive vs dissipative.

Overview learn about esd flooring short videos conductive vs dissipative.

It isn t as simple as measuring samples right out of the box.

There are several esd floor test methods associated with and recommended by voluntary associations with a keen focus on the phenomenon and control of static electricity in work environments.

Do not clean surface.

There are two distinct phases to evaluating and selecting esd flooring.

Pip s certified esd plant auditors obtain a thorough understanding of the fundamentals of esd.

Here s one proposed solution to the floor testing problem.

5 reasons to put vermont slate on your esd flooring short list for 24 7 critical environments how is commercial carpet different from esd carpet testing and certification of esd floors buying esd flooring on the internet the case against overly.

Esd sensitive devices shall also be removed.

Let s go through the entire process step by step.

A static control garment has 1 x 10 11 ohms surface resistance measured point to point on the garment.